Lean Six Sigma Green Belt Certification Training in Pakistan

Lean Six Sigma Green Belt Certification Training in Pakistan

Conduct Procedure Advancements and Expand Rate with Six Sigma Green Belt Skills.

3K+ Enrolled

Accredited by

Accredited by

Lean Six Sigma Green Belt Certification Training in Pakistan

5.0

3K+ Enrolled

Conduct Procedure Advancements and Expand Rate with Six Sigma Green Belt Skills.

Accredited by

Guaranteed to Run Workshops

Expert-Led Study Sessions

Networking Opportunities

Flexible Monthly Payment Plans

Real-World Case Studies

Hands-On Project Experience

Request More Details

450K+

Professionals trained

250+

Workshops every month

30+

Trainers

450K+

Professionals trained

250+

Workshops every month

20+

Trainers

Course Overview

The Lean Six Sigma Green Belt Certification Training course is vital for professionals who want to improve their development strategies. This certification delivers deep learning of Six Sigma green belt tools and methodologies, concentrating on decreasing process variability and driving process advancements across various industries.

Participants in this course acquire powerful analytical and problem-solving skills, allowing them to manage quality refinement projects effectively. The training combines Lean principles with Six Sigma processes, eliminating waste and boosting working efficiency. Therefore, Lean Six Sigma Green Belt experts are highly sought after in the job market.

This course aligns with the Lean Six Sigma Green Belt, the globally recognized accreditation body, IASSC. With a realistic approach that includes real-life strategies, participants gain hands-on experience to apply these procedures in their professional roles. Simpliaxis delivers this course, qualifying people to excel in the Six Sigma Green Belt certification exam and achieve career success.

Also, check:How to Pass the Six Sigma Green Belt Exam

SSGB Training Highlights

Twenty-four hours of live training sessions.

Complete the sessions with our expert trainer and earn 24 PDUs.

End-to-end exam preparation support and guidance.

Explore practical experience with industry case studies.

Lifetime access to the course learning material

Hands-on learning with real-world projects.

Doubt cleaning sessions

24/7 training support

Career upliftment

Unsure about your prep?

Benefits focused on Individuals and corporate

Common attendees

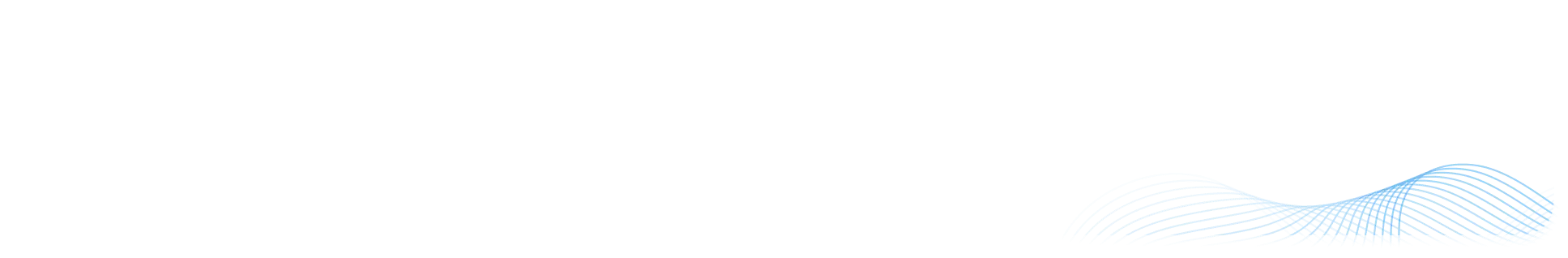

Healthcare Quality Coordinator

Project Manager

Financial Analyst

Quality Assurance Manager

Manufacturing Engineer

Process Improvement Specialist

Operations Manager

Business Analyst

Continuous Improvement Manager

IT Professionals

Prerequisites for SSGB certification training

Eligibility:

Get the SSGB Certification

Curriculum

1.1 What is Six Sigma

Six Sigma is a structured, data-driven methodology used to improve process performance by reducing variation and eliminating defects. A defect is defined as any outcome that does not meet customer requirements. Six Sigma aims for a performance level of no more than 3.4 defects per million opportunities (DPMO).

1.2 History and Evolution

1.3 Benefits of Six Sigma

1.4 Six Sigma Roles and Responsibilities

1.5 Lean vs Six Sigma

1.6 DMAIC Overview

2.1 Objective of Define Phase

To clearly define the problem, project scope, goals, and customer requirements.

2.2 Project Selection

2.3 Project Charter

Key Elements:

Example (Manufacturing):

2.4 Voice of the Customer (VOC)

VOC represents customer needs and expectations.

VOC Collection Methods:

Example (Service): Customer complaints about long turnaround time (TAT)

2.5 CTQ (Critical to Quality)

CTQs translate customer needs into measurable requirements.

VOC → CTQ Example:

2.6 SIPOC Diagram

When to use: Early Define phase

Common mistakes: Too much detail; unclear process boundaries

2.7 High-Level Process Mapping

Provides an overview of the current process flow.

2.8 Stakeholder Analysis

Identifies key stakeholders and their influence on the project.

Deliverables of Define Phase:

3.1 Objective of Measure Phase

To understand current process performance and establish a baseline.

3.2 Types of Data

3.3 Data Collection Plan

Includes what data to collect, how, when, and by whom.

3.4 Operational Definitions

Ensures consistency and clarity in measurement.

3.5 Sampling Methods

3.6 Measurement System Analysis (MSA)

Evaluates accuracy and precision of measurement systems.

Key Concepts:

3.7 Basic Statistics

3.8 Process Capability

3.9 Graphical Analysis

4.1 Objective of Analyze Phase

To identify and validate root causes of defects and variation.

4.2 Process Mapping (Detailed)

Helps identify non-value-added steps.

4.3 Root Cause Analysis Tools

4.4 Failure Mode and Effects Analysis (FMEA)

4.5 Hypothesis Testing Basics

4.6 Common Hypothesis Tests

4.7 Correlation and Regression

Used to understand relationships between variables.

5.1 Objective of Improve Phase

To develop, test, and implement solutions that address root causes.

5.2 Solution Generation Techniques

5.3 Solution Selection Tools

5.4 Lean Tools for Green Belts

5.5 Pilot Implementation

Testing solutions on a small scale.

5.6 Risk Analysis

Identifying and mitigating risks before full implementation.

5.7 Introduction to DOE

6.1 Objective of Control Phase

To sustain improvements and prevent regression.

6.2 Control Plan

Defines how the process will be monitored and controlled.

6.3 Standardization

6.4 Visual Controls

Make process status visible and clear.

6.5 Control Charts

6.6 Reaction Plan

Actions to be taken when a process goes out of control.

6.7 Project Closure

7.1 Introduction to Minitab

7.2 Data Entry and Management

7.3 Statistical Analysis Using Minitab

7.4 Interpreting Minitab Output

8.1 Project Requirements

8.2 Tollgate Reviews

8.3 Project Presentation and Certification

Appendix

Course Curriculum

1.1 What is Six Sigma

Six Sigma is a structured, data-driven methodology used to improve process performance by reducing variation and eliminating defects. A defect is defined as any outcome that does not meet customer requirements. Six Sigma aims for a performance level of no more than 3.4 defects per million opportunities (DPMO).

1.2 History and Evolution

1.3 Benefits of Six Sigma

1.4 Six Sigma Roles and Responsibilities

1.5 Lean vs Six Sigma

1.6 DMAIC Overview

2.1 Objective of Define Phase

To clearly define the problem, project scope, goals, and customer requirements.

2.2 Project Selection

2.3 Project Charter

Key Elements:

Example (Manufacturing):

2.4 Voice of the Customer (VOC)

VOC represents customer needs and expectations.

VOC Collection Methods:

Example (Service): Customer complaints about long turnaround time (TAT)

2.5 CTQ (Critical to Quality)

CTQs translate customer needs into measurable requirements.

VOC → CTQ Example:

2.6 SIPOC Diagram

When to use: Early Define phase

Common mistakes: Too much detail; unclear process boundaries

2.7 High-Level Process Mapping

Provides an overview of the current process flow.

2.8 Stakeholder Analysis

Identifies key stakeholders and their influence on the project.

Deliverables of Define Phase:

3.1 Objective of Measure Phase

To understand current process performance and establish a baseline.

3.2 Types of Data

3.3 Data Collection Plan

Includes what data to collect, how, when, and by whom.

3.4 Operational Definitions

Ensures consistency and clarity in measurement.

3.5 Sampling Methods

3.6 Measurement System Analysis (MSA)

Evaluates accuracy and precision of measurement systems.

Key Concepts:

3.7 Basic Statistics

3.8 Process Capability

3.9 Graphical Analysis

4.1 Objective of Analyze Phase

To identify and validate root causes of defects and variation.

4.2 Process Mapping (Detailed)

Helps identify non-value-added steps.

4.3 Root Cause Analysis Tools

4.4 Failure Mode and Effects Analysis (FMEA)

4.5 Hypothesis Testing Basics

4.6 Common Hypothesis Tests

4.7 Correlation and Regression

Used to understand relationships between variables.

5.1 Objective of Improve Phase

To develop, test, and implement solutions that address root causes.

5.2 Solution Generation Techniques

5.3 Solution Selection Tools

5.4 Lean Tools for Green Belts

5.5 Pilot Implementation

Testing solutions on a small scale.

5.6 Risk Analysis

Identifying and mitigating risks before full implementation.

5.7 Introduction to DOE

6.1 Objective of Control Phase

To sustain improvements and prevent regression.

6.2 Control Plan

Defines how the process will be monitored and controlled.

6.3 Standardization

6.4 Visual Controls

Make process status visible and clear.

6.5 Control Charts

6.6 Reaction Plan

Actions to be taken when a process goes out of control.

6.7 Project Closure

7.1 Introduction to Minitab

7.2 Data Entry and Management

7.3 Statistical Analysis Using Minitab

7.4 Interpreting Minitab Output

8.1 Project Requirements

8.2 Tollgate Reviews

8.3 Project Presentation and Certification

Appendix

What you will learn in this SSGB workshop

Lean and Six Sigma Principles:

Understand the concepts of Lean methodology for waste reduction and techniques for minimizing processes.

Process Improvement:

Learn how to manage process mapping, root cause analysis, and process improvement analysis to identify and improve the work process.

Data-Driven Decision Making:

Boost expertise in collecting and analyzing data to make informed, evidence-based decisions.

Project Management:

Acquire skills to lead and manage Six Sigma projects, ensuring successful process improvements.

Poor Waste Elimination:

Learn how to recognize and eliminate waste to improve efficiency, reduce costs, and expand productivity.

Quality Improvement:

Understand how to enhance product and service quality, improving customer happiness.

Cooperation and Supervision:

Develop leadership skills to guide teams in managing process improvements and working collaboratively across departments.

40+ Certification programs made an impact

Employee retention improved by 45%

Work satisfaction and capabilities improved by 30% on an average

100+

Clients

SSGB Certification Course For Corporates

With learning targeted to your unique team environment, we at SimpliAxis help to resolve your specific issues and meet your specific needs with tailored training methods. We offer corporate training globally to keep Organizations up to date by building the knowledge gap required and make them strive in the competitive world with the right skills according to the industry needs.

Our Customer words for us

Meet the Team That's Invested in Your Success

What is Lean Six Sigma Green Belt training?

Who should pursue Lean Six Sigma Green Belt certification?

Are there prerequisites for Lean Six Sigma Green Belt certification?

What topics are covered in Lean Six Sigma Green Belt training?

What skills do I gain from Lean Six Sigma Green Belt certification training?

How long is Lean Six Sigma Green Belt training?

What is the cost of Lean Six Sigma Green Belt training?

Does LSSGB certification include an exam?

Is Lean Six Sigma Green Belt certification worth it?

Is Lean Six Sigma Green Belt training suitable for non-manufacturing sectors?

How does Lean Six Sigma Green Belt certification impact salary and career growth?

What happens to my token or partial payment if I don’t enroll immediately?

Is there a preferred currency for payment, especially for international students?

Can payments be made online through your website, or do I need to visit a physical location?

Do you offer any discounts or promotions for early payment?

Can I pay for the course in installments, or is full payment required upfront?

Will I get a refund if I cancel my enrollment?

Where will I get my payment receipt?

Is there any transaction or processing fee?

What cards do you accept?

What payment options are available?

What if I miss a class? Are there any money back options?

If I want to know more about Training, whom should I connect with?

Is there any option to complete the Training in the native language if a participant chooses to?

Can I receive personalized Training at my convenience?

Where do I find the upcoming schedules of my course?

After enrollment, can I change the date of my training class?

Do I get any certificate upon completion of the course?

How do I enroll in the training course?

What are the different courses offered by Simpliaxis?

What are the different modes of Training available for Simpliaxis courses?

Do you offer online Training?

Do you offer corporate Training?

Who are the instructors of my course?

Is there any discount available for the Simpliaxis courses?

Whom do I contact if I have more queries regarding my course?

Are your courses affordable?

Why should I choose Simpliaxis?

What is the object of Simpliaxis?

How much discount will I get if I enroll for the Training?

SSGB Course FAQs

Lean Six Sigma Green Belt training usually spans 4 weeks for the instructor-led programs. On the other hand, online and self-paced options may span several weeks, allowing participants to align their training with professional responsibilities.

You can reach out to our experienced career counselor

or email us on support@simpliaxis.com

or contact any of our phone numbers

or you can chat with us anytime

or visit our contact us page https://www.simpliaxis.com/contact-us

Find out why 1,000+ professionals love SimpliAxis