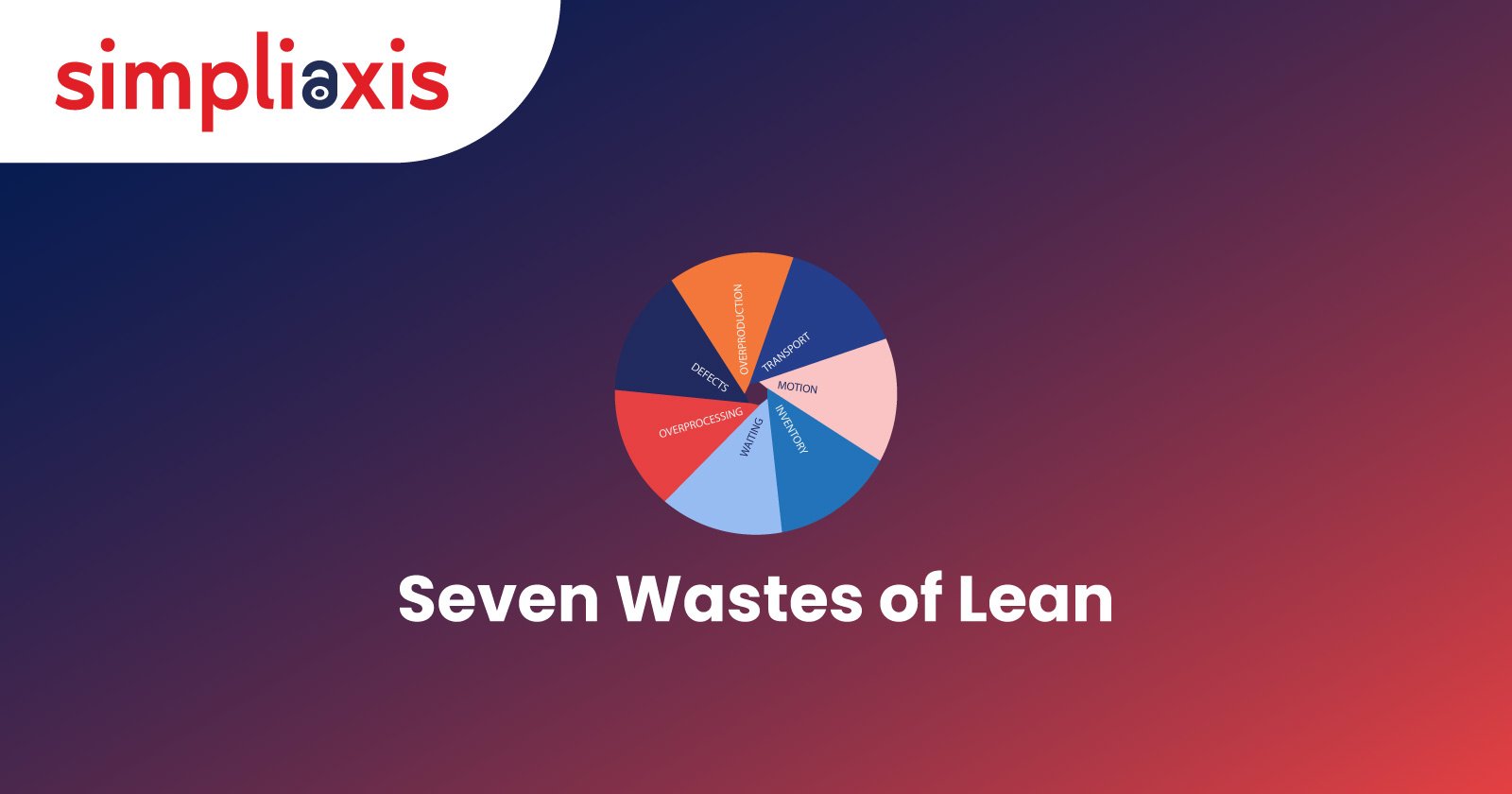

Lean manufacturing is a management philosophy. This philosophy was derived from the Toyota Production System. This system's main focus is to eliminate waste in the production process, which is referred to as Muda. The good thing about this philosophy is that it considers different types of garbage encompassing high levels of human motion. By eliminating waste, this system aims to combine every step of production into an efficient and holistic process that improves overall revenues and reduces costs. When it aims at eliminating waste, still 7 wastes of lean are common in lean manufacturing. We are here to throw some light on these wastes of Lean Production:

Know About Muda, Mura, and Muri:

Eliminating wasteful activities is one of the most crucial requirements for building a successful organization. This concept is crucial in Lean thinking, and by paying attention to eliminating waste, Lean aids in improving productivity in any organization.

As mentioned earlier, the idea of waste elimination originated from the Toyota Production System. One of the founding fathers of Lean Manufacturing, Taiichi Ohno, dedicated his entire career to establishing an efficient and solid work process. In this journey, Ohno explained three crucial hindrances that can negatively affect an organization’s work in progress. He describes these blocks as Muda, Muri, and Mura. The first denotes wasteful activities, the second denotes overburden and the third is unevenness. Based on his findings after deep analysis, Ohno categorized seven waste of lean, otherwise called 7 mudas. It later became a familiar practice for resource optimization and cost reduction.

Meaning of Muda or Lean Waste:

In Lean, waste denotes any activity that consumes resources. Even though resource consumption happens, it does not bring any value to the end-user. However, of the entire work in progress in an organization, only a small percentage can bring value to consumers. This is why it is recommended that organizations pay attention to bringing down wasteful activities as much as possible. When they do this, organizations can identify considerable opportunities for improving their performance. However, the thing to remember here is that it is impossible to eliminate all wasteful activities from the work in progress. The reason is that some wastes are necessary. For instance, software testing in a software development company is not an activity customers pay for. Nevertheless, without testing the software, it might not be possible for the software development company to deliver the best-quality software. So, you can categorize the waste into two main categories. They are necessary wastes and pure wastes.

Necessary wastes do not add any value, but they are essential to getting things done qualitatively. Examples of these activities can be reporting, planning, and testing.

Pure wastes also do not add any value but are different from necessary wastes because they are not required. These wastes include activities that do not bring any value and can be removed from the process immediately. You can describe any form of waiting, otherwise known as waiting waste as pure waste.

Meaning of Mura:

Mura denotes the waste of inconsistency and unevenness in Lean Six Sigma. It can have more than a single manifestation based on the nature of your business. A pre-requirement for unevenness is the inefficiency to straighten your process and create a balance in activities. As an outcome, your team will put its efforts into the process as quickly as possible. They will start producing one big batch over the other without any thought or with a little thought of how the process will withhold the burden.

Meaning of Muri:

Muri will occur when you put your team under much stress by demanding unnecessary and unreasonable work far beyond their capacity. You can understand that Muri can bring down not only the efficiency but also the productivity of your team due to overburden. When you put a lot of pressure on them, your team members must extend their working hours. In turn, it can contribute to occupational burnout. Overburdening can affect the morale of your team a lot. It can even damage the entire healthy production process.

It is like giving a lot of work to three team members just because they are performing well. When you do this, they can get sick, affecting the entire process. The idea here is to balance at the optimal capacity. This is the level at which every portion of the system can deliver outcomes without requiring additional work.

Muri occurs when one resource is overburdened with many tasks while the other waits at the same time. Otherwise, it is where under-utilization of some resources and over-utilization of some resources take place, thereby creating an overburden on the latter. When this happens, your processes will become less predictable, and your team will start struggling to deliver value at a steady pace.

Now, you know about Mura, Muri and Muda. Of these three, the 7 wastes of lean management come under Muda. Here are the details about these 7 wastes.

7 Muda or Wastes in Lean Sigma:

1. Transport:

Among seven types of waste lean, transportation waste is also one of them. Waste in transportation encompasses the movement of products, equipment, inventory, tools and people. Of course, transportation becomes essential. But, the waste includes transportation that happens more than the required limit. The reason is that excessive movement of raw materials can contribute to product defects and damage. When people move more often, it can lead to exhaustion. When raw materials move a lot, there is a chance of greater wear and tear. In the same way, excessive movement of both people and materials can lead to unwanted work. When you take the case of a factory, raw materials required for production should easily be accessible to workers. Here, triple or double handling of materials should be avoided. Some of the countermeasures to waste of transportation encompass the development of a U-shaped production line. In turn, it will create a flow between processes. It will help avoid overproduction of items in the work-in-process.

2. Inventory:

Many items in the Work-in-process result from overproduction and waiting. This contributes to the excess stock of produced goods on the plant floor. When products wait in the inventory for a long time, manufacturing units will have to spend a lot. The reason is that management needs resources to manage those items in the inventory. Also, the space occupied by the inventory can be used to store raw materials required for the next production cycle when sudden orders come up.

3. Motion:

When discussing the seven wastes of lean, transportation and the motion of people and machines from one place to another is considered a waste. Here, motion can denote anything from a worker bending down to pick up a raw material required for production. It is believed that unnecessary motion can lead to extended time to produce, injuries, etc. In other words, to prevent this waste, you must do whatever is required to arrange a process so that employees do not have to make many movements to finish their work.

4. Waiting:

Waiting denotes the waiting a person or machinery must do to complete a task. This waiting is common when one process in production takes longer to complete than the time expected for completion. When this happens, production time is wasted. When waiting for production, materials can be spoiled, while workers should be paid even for the waiting time. In turn, the cost to the company will increase.

5. Overproduction:

If you have been in the manufacturing field for a long time, you know overproduction is the most obvious form of waste. Apart from contributing to depleted raw materials, it can also contribute to wasted storage and more funds locked up in unused products.

If your team consistently produces more, based on the nature of your product, you might be forced to dispose of some products. There is a chance that you will cause environmental damage when you do this. Disposal also leads to a waste of human effort. Even, there are chances of risk of exposing your workforce to harmful waste materials.

Your team and your organization should aim to produce only what customers need. Lean Manufacturing depends on a 'just-in-time' policy. It means that a product should be made only at the time it is required and not early.

6. Over Processing:

Overproduction and overprocessing are among the seven wastes of lean management. Overproduction means doing more work, adding more components, or having more steps in the service or product than customers need. For instance, using higher precision equipment than required denotes overprocessing. Using components with capabilities more than what is required is also overprocessing.

7. Defects:

One of the confirmed defects among the 7 lean wastes is the defect in the product. But, the problem with this waste is that it remains unnoticed until the products reach customers. Errors in quality that lead to defects can cost you far more than your expected. When an item is defective, it needs replacement or reworks. In turn, both materials and resources become waste. It can lead to customer dissatisfaction and even a lot of paperwork. So, preventive actions should be taken to avoid defects. For instance, automation and poka-yoke systems can help with defect prevention.

Conclusion:

The seven types of waste lean are shortly referred to as TIMWOOD. You can relate each letter in this term to the appropriate wastes above. Even for easy memory, the 7 together are otherwise called WORMPIT, which means waiting, overproduction, rejects, motion, processing, inventory, and transport. These wastes represent inefficiencies in manufacturing processes that can impede productivity and increase costs. By identifying and addressing these wastes, organizations can streamline operations, improve resource utilization, and enhance efficiency. Adopting lean principles allows companies to continuously optimize their processes, minimize waste, and deliver greater customer value.

Simpliaxis offers Six Sigma courses that cover various levels of expertise, from introductory to advanced. These courses equip professionals with the knowledge and skills to lead process improvement initiatives, reduce defects, and enhance organizational efficiency. Whether you're new to Six Sigma or aiming for mastery, Simpliaxis provides comprehensive training tailored to your needs.