The present business world is experiencing a high level of competition. Therefore, every business these days looks for a method to get the best output and productivity without spending much. One technique that has gained immense popularity for helping businesses reduce waste, thereby saving on costs is Six Sigma. Studies show that Six Sigma Black Belt holders are saving nearly $230,000 per project. Even, they are known for their efficiency in completing more than 4 to 6 projects in a year.

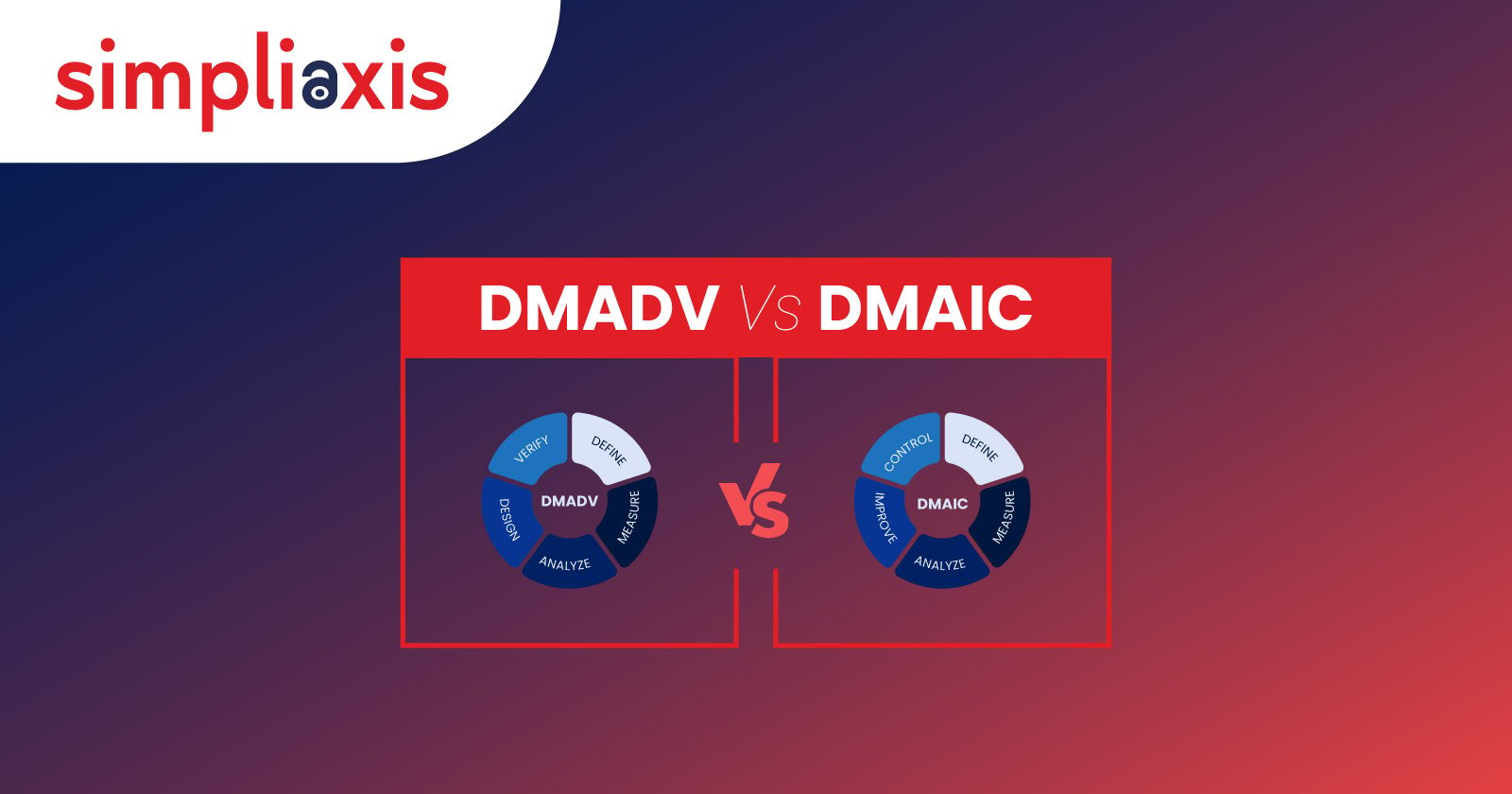

Indeed, Six Sigma has proven its efficiency. However organizations find it confusing whether to choose DMAIC or DMADV Framework. Green-belt holders of Six Sigma often practice the DMAIC framework. They use this framework mainly to improve the processes that they already follow. However, here comes the question of what should be done if the process should be redesigned for improvement. This is where the DMADV framework can help. It refers to the circumstance, where a process improvement becomes possible when a green belt-holders looks for an improvement. Before comparing DMADV vs DMAIC, it is better first to gain a fundamental understanding of these two concepts:

DMADV and DMAIC – Understanding the Basics:

DMADV:

DMADV pays attention to the process of designing a new process, service, or product. Each letter in this framework has a meaning as given below:

- Define: Outline the procedure and goals of the design

- Measure: Gauging the spotting quality-crucial features of the product, process or service being designed. This encompasses product and risk capability assessment.

- Analyze: Examination of the data to spot the ideal design

- Design: Creating the blueprint and testing the service, product or process.

- Verify: Make sure that the output of the design gets in line with the design input needs. Also, it involves ensuring that the designed product performs at its best under simulated or real conditions or intended use.

DMAIC:

When compared to DMADV, DMAIC is the most-used and popular method. Its objective is to bring improvement to an existing process by encompassing the steps listed below:

- Define: It involves outlining the issue, output to be improved, process and customers associated with the issue.

- Measure: Gather information and data for the process so that it will be possible to establish a foundation for improvements.

- Analyze: Evaluate the data to spot the root cause of the issue.

- Improve: Create, evaluate, and put the solutions into practice for improving the process.

When To Use?

Understanding the difference between DMAIC and DMADV is important. However, it is equally important to know which framework to use and when. Here are the details:

DMAIC:

This technique can be used only when the product has been released already out of the organization. It should be applied when issues are spotted in the product. Otherwise, it should be used when the product goes away from what the customers have demanded previously.

DMADV:

This methodology is used when the product is yet to be designed. For instance, if you are engaged in the designing of a product, service or process for your organization and are presently in the planning and designing stage, DMADV can help. Also, this technique will be helpful when the product cannot be optimized and needs rebuilding.

Also, Check:Six sigma dmaic process and methodology

What are the Similarities?

Indeed, we will throw some light on Six Sigma DMAIC vs DMADV. But, before getting into the differences, you should understand how these techniques are like each other:

Many things in these two processes are similar and they are worth taking into consideration as well. For instance, both use statistical facts and tools to find and bring out a remedy to common issues related to quality. Both pay attention to reaching the financial and overall business goals. Also, both are implemented by Master Black Belts, Black Belts and Six Sigma Green Belt holders. They help bring down the defects to a great extent. Both are data-intensive and use hard facts to spot solutions but in different phases of product development and even after the release of the product.

Also, Check:Difference Between Yellow, Green, and Black Belt Six Sigma

Comparison Chart:

Here is a basic DMADV vs DMAIC comparison before we get into a detailed understanding of the difference between DMAIC and DMADV:

S. No. | Point of Comparison | DMADV | DMAIC |

1. | Purpose | It seeks to design a new process, product or service or improve an existing process, product, or service. | It attempts to improve the existing process or product or service |

2. | Process type | Proactive Approach | Reactive Approach |

3. | Focus | Focused on customers | Pays attention to processes. |

4. | Team Strength | Needs a large team | Small team |

5. | Period | Long term | Short to medium-term |

6. | Time of Use | When reengineering is needed | When continuous improvement is required |

7. | Tools used | Qualitative tools | Quantitative and statistical tools |

8. | Implementation time | When an evolutionary modification is required | When an incremental modification is required |

Now, you have gone through the fundamental comparison of Six Sigma DMAIC vs DMADV. Here, you can get a deeper understanding of the differences between these two approaches:

Deeper Understanding of the Differences Between DMAIC and DMADV:

From the flowchart below, you can understand how these frameworks differ from each other. When you see the picture below after the Define Phase, based on the presence of the process, if it exists, DMAIC gets into the picture. But, if it does not exist, the DMADV Framework is followed:

From the points below, you can understand DMADV vs DMAIC better:

- The latter focuses on reducing variation in a process that exists. On the other hand, the former is about producing a process that is the first time right.

- When the latter is a corrective measure, the former is preventive.

- The latter takes help from statistical tools, while the former uses qualitative tools.

- DMAIC pays attention to crucial QTC parameters, while the other technique pays attention to all of them.

- When DMAIC is short-term, DMADV is a long-term approach.

When you intend to use a Six Sigma approach, you should know that this practice is not restricted to a particular type of issue or procedure. Most organizations believe that it is a technique for manufacturing organizations alone. But, in reality, it helps improve the process in any atmosphere. Further, it is not restricted to improving an existing process. Yes, you can use it when you are engaged in the designing of a new process entirely. With DMADV, you can think out-of-the-box and can entirely redesign processes that were not properly created earlier. It is not possible to fix this issue with the DMAIC approach.

The key difference between DMAIC and DMADV techniques lies in the kind of projects in which they are used. When the former is used for improving existing processes, the latter is used for the development of new solutions, products or processes with better dependability. Nevertheless, the fundamental principles that these two techniques follow remain the same. Both need a clear definition of the issue and they need a complete understanding of the present situation. Further, both these techniques require the teams to be committed to solving the issues faced by customers.

Tools Used:

In this Six Sigma DMAIC vs DMADV comparison, you should be aware of the different tools these two methodologies use:

DMAIC:

For Defining:

- Project Charter

- SIPOC

- VOC Questionnaire

For Measuring:

- Measurement Systems Analysis

- Kano Model

- Benchmarking

For Analyzing:

Hypothesis Testing

- 5 Whys

- Regression Analysis

For Improving:

- FMEA

- Simulation

- Mistake Proofing

- For Controlling:

- Control Plan

- Process Sigma Calculation

- Control Charts

DMADV:

To Define:

- Project Charter

- SIPOC

- VOC Questionnaire

To Measure:

- Kano Model

- RACI Matrix

- Check Sheets

To Analyze:

- Brainstorming

- Affinity Diagram

- QFD

To Improve:

- iTRIZ

- Design of Experiments

To Verify:

- Standard operating procedures

- PDPC

These are examples of tools used by Six Sigma Belt holders. Nevertheless, some black belt holders can use other tools as well to find the right solution to the issues based on whether they use the DMADV or DMAIC Approach.

Conclusion:

Now, you are aware of the differences in this DMADV vs DMAIC comparison. After comparing the differences and similarities, you might now be aware of the fact that DMAIC can help with the already existing process or product. However, you can use it when the product or process is not in a position to meet the requirements of customers or their specifications.

On the other hand, DMADV is used when a process or product is to be developed to meet the needs of customers. Even, this technique will help your organization when you intend to optimize a process or product.

Organizations without prior experience in Six Sigma can get help from Master Black Belts and Black Belts in Six Sigma. These professionals can provide the right guidance when it comes to selecting between these two techniques. Even, these professionals can provide the right guidance during the implementation stage and this is something important for the success of any Six Sigma initiative or project. Simpliaxis offers comprehensive Six Sigma courses to equip professionals with the knowledge and skills needed to excel in process improvement. Start your journey toward operational excellence with Simpliaxis today!